HARSB removes residential and non-residential pollution EVERY DAY !!

--

On the Average, each person in the U.S. contributes 50-100 gallons of wastewater

each day.

If we

don't remove pollution the river and aquifer become polluted and quality of

life in the valley

would decrease.

-- A Wastewater Treatment plant

removed solids: This includes everything from rags, sticks, rocks, sand, etc.

found in wastewater

-- A Wastewater Treatment plant reduces organic matter

and pollutants: Helpful bacteria and other microorganisms are used to consume

organic

matter in wastewater. The bacteria and

microorganisms are then separated from the water

-- A Wastewater Treatment

plant restore oxygen: Treatment facilities help ensure that the water put

back into our lakes or rivers has enough

oxygen to

support life.

Note: While our lakes and streams clean water in much the

same way, wastewater treatment plants are faster and can handle more water.

This makes

treatment plants essential in areas where there's too much

wastewater for nature to handle alone.

Let Us Start a Basic Tour of the HARSB Facility:

Headworks:

The headwork's receives influent from the City of Hayden, Hayden

Lake Recreational Water and Sewer District, and Kootenai County Airport.

Inside the Headworks is the Step Screen and Grit System.

The Step Screen removes materials that should not be in the system. The material that is removed is sent to the Landfill.

Equalization Tank and Biological Nutrient Flow Control

The Flow Control Valve is set for a daily flow rate and is measured by a flow

meter. The set flow rate is at 1 million gallons per day to the biological

process.

Excess flows above 1 million gallons per day in the morning flows

into the equalization tank. In the afternoon and the middle of the night

when water flow rates

drop below 1 million gallons per day, water is pumped

from the equalization tank to maintain the constant flow and organic load to the

biological process.

Anaerobic Tanks and Anoxic Tanks

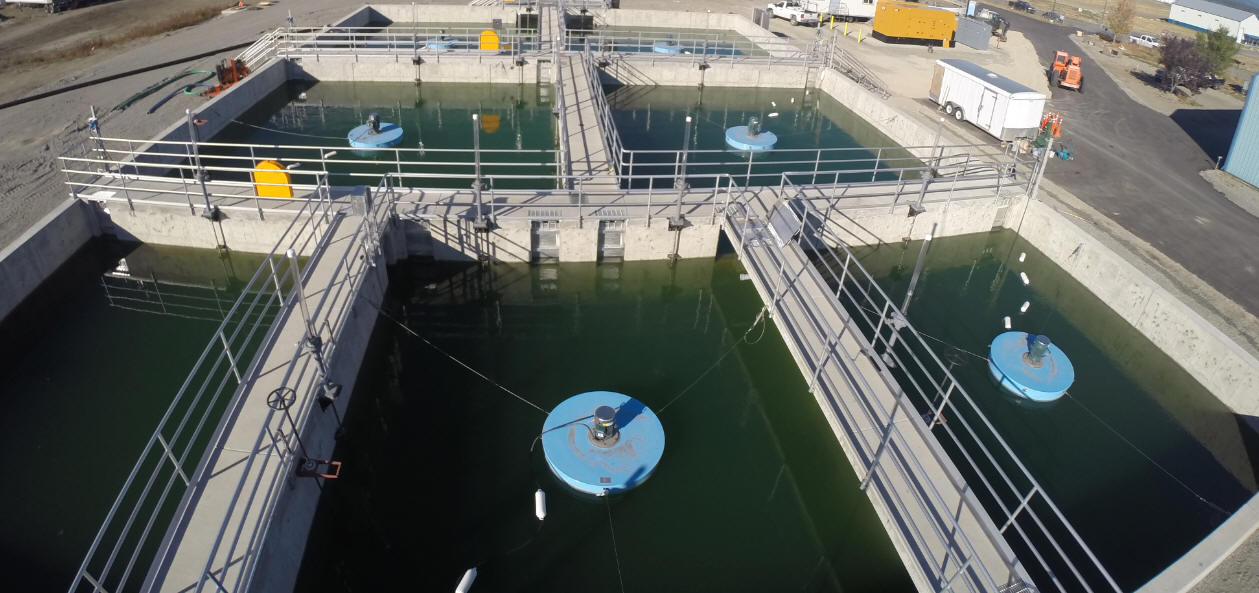

Oxidation Ditches

Surface aerators provide high oxygen aerobic conditions. Bacteria eat organics, consuming oxygen (02), and make more bacteria (solids) "Eating and Reproducing"

Clarifiers

Waste Sludge Holding Tank

The solids are removed from the Clarifier and placed in the holding

tank. Air is pumped into the tank to maintain high dissolved oxygen

condition to keep the solids

fresh and easier to dewater.

Chlorine Disinfection

Chlorine gas is added to water to make a strong chlorine

solution. Chlorine kills disease causing organisms. Water is

then recycled to the Spokane River during winter months

or to the Reuse Farm

during the growing season.

Fact: "Chlorine Disinfection is credited for the

large increase in world population growth in the 20th Century because it kills

disease causing organisms."

Screw Press (DeWatering)

Polymer is added to make the solids stick together and release water. The press squeezes the water from the solids making dryer biosolids (cake). Biosolids meet EPALaboratory

On site testing to control the biological process and monitor the water to insure it meets water quality requirements.